Reimagining Cold Chain Visibility for Food

Optimise Your Cold Chain With Real-Time Visibility

The cold chain is often complex. And despite best efforts, unexpected temperature fluctuations, inaccurate records, insufficient monitoring, transit delays, equipment failure, and more, are stubborn issues which lead to degradation and waste (all stats below are annual):

2.4 million

£9 billion

3.7 million tonnes

50%

With our expertise in track and trace solutions, and using both existing and new approaches from Zebra Technologies, we can assist you in reimagining the cold chain. With electronic sensors, temperature sensitive labels and monitors, and mobile computing solutions, you can gain a real-time view over the status of produce from farm to fork – and every step in between.

However complex or simple your supply chain is, and whatever the size of your business, the inexpensive solutions empower your teams to collect and view accurate records, immediately identify temperature excursions and take informed decisions that protect the quality of produce in your care.

Versatile Cold Chain Solutions

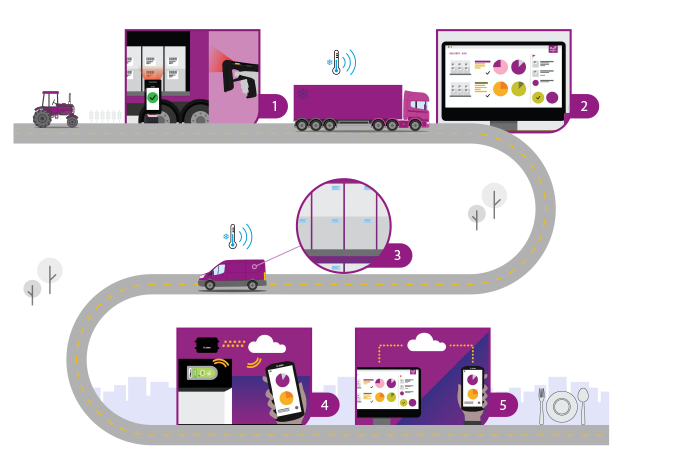

1. Warehouse and supply chain: Tracking and tracing consignments

Using RFID labels and tags, you can uniquely identify food items (including origin, sell-by date). And, with fixed and handheld readers, automatically log inventory into and out of facilities as it moves from the farm to the warehouse, across deliveries, to distribution centres and to its final destination.

2.Transit: Real-time data insights across the supply chain

Compact, wireless electronic temperature sensors and data loggers provide a stream of temperature and location data from pretty much any shipment. Teams transporting products can view data on their AndroidTM mobile devices, while those at HQ can track a consignment’s status in the cloud. The data helps them make informed, confident decisions.

3. Food monitoring: Visual, per item alerts for temperature excursions

With temperature-sensitive labels and monitors attached to food and packaging, teams (and consumers) have an instant, visual view if a temperature limit has been met or exceeded.

4. Workflow efficiency: Automated data capture

With mobile devices, your teams can easily capture RFID

data to enhance the tracking and tracing of items and use template forms to quickly manage a range of tasks – from

proof of delivery and reporting issues or spoilage to recording temperatures, and much more. Handheld devices and vehicle- mounted computers withstand various levels of condensing environments as goods are stored and moved, with temperature logging at -22°F/-30°C.

5. Real-time insights: Get the complete picture in the cloud

Data from your sensors and devices can be shared across the cloud and used by AI-powered demand intelligence software to help drive smarter decisions.

Range of Benefits

With visibility into every corner of cold chain operations, you can:

-

Monitor environmental exposures to preserve the quality, taste and freshness of produce

-

Enhance workflow efficiencies and increase productivity

-

Help your supply chain teams make more informed, and faster, decisions about items in their care

-

Reduce waste

-

Create auditable records and automatically generate reports for legislation and compliance purposes

-

Improve service to customers

- Enhance collaboration between supply chain parties

The solutions outlined in the paper are simple to put in place and use. In many cases they’re customisable too: for example, labels and monitors can include your logo. To learn more about how we can help you gain greater visibility over your cold chain, please:

Contact us at: sales@cls.uk.com